Level

Level measurement is critical in industrial applications where precise monitoring of liquid, slurry, or solid levels is necessary. Nasha Automation specializes in providing advanced level measurement solutions for a variety of industries, including petrochemical, chemical, oil & gas, water treatment, and more. Their expertise lies in offering reliable, accurate, and cost-effective instrumentation for measuring levels in tanks, vessels, silos, and pipelines.

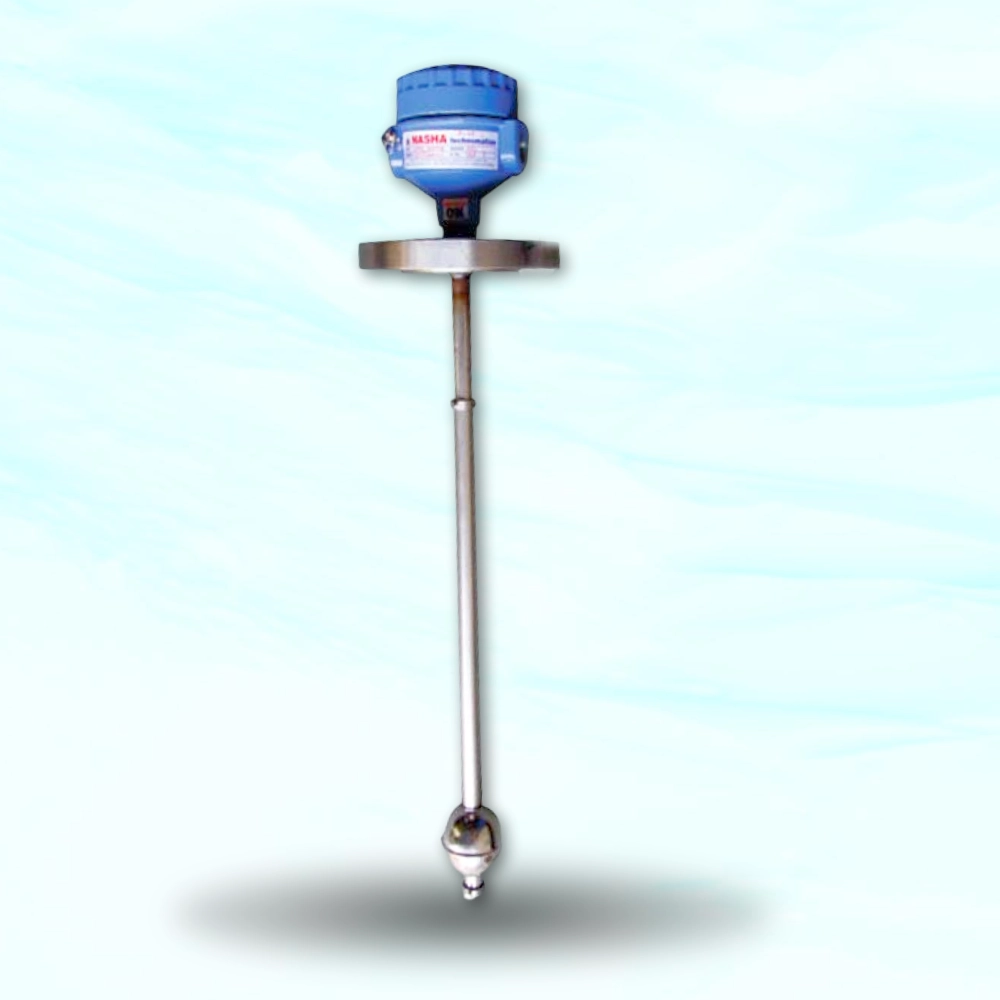

Top Mounted Float Type Level Switch and Transmitter

The Top Mounted Float Type Level Switch and Transmitter is a widely used level measurement and control device that provides accurate and reliable monitoring of liquid levels in tanks, vessels, and other storage containers. This technology is particularly ideal for applications where precise level detection is crucial, such as in water treatment, chemical processing, food and beverage, and oil & gas industries.

Technical Specification

| Specification | Details |

|---|---|

| Material of Construction | Stainless Steel, PVC, or other corrosion-resistant materials |

| Temperature Range | -20°C to 150°C (varies with model) |

| Pressure Range | Up to 20 bar |

| Output Signal (for Transmitters) | 4-20mA, HART, or digital protocols |

| Accuracy | ±1-2% of full-scale output |

| Switching Capacity (for Level Switch) | Up to 240V AC or 24V DC |

| Mounting | Top-mounted design |

| Float Material | Stainless Steel or Non-corrosive materials |

| Application Areas | Water Treatment, Oil & Gas, Chemicals, Food & Beverage, Pharmaceuticals |

| Features | Reliable, Cost-effective, Versatile, Low maintenance |

Side Mounted Magnetic Level Switch

The Side Mounted Magnetic Level Switch is a reliable and cost-effective solution for liquid level detection and control in various industrial applications. This device is widely used in applications where a side-mounted installation is preferred for measuring liquid levels in tanks, vessels, and pipelines, particularly when top access is unavailable or impractical.

Technical Specification

| Specification | Details |

|---|---|

| Material of Construction | Stainless Steel, PVC, PTFE (depending on application) |

| Temperature Range | -20°C to 150°C (varies by model) |

| Pressure Range | Up to 20 bar |

| Output Signal | SPDT contacts, NAMUR (for intrinsically safe applications) |

| Accuracy | ±1-2% of full-scale output |

| Switching Capacity | Up to 240V AC or 24V DC |

| Mounting | Side-mounted with flange connection |

| Float Material | Stainless Steel, PVC, or other corrosion-resistant materials |

| Application Areas | Water Treatment, Chemical Processing, Food & Beverage, Oil & Gas, Pharmaceuticals |

| Features | Reliable, Easy Installation, Low Maintenance, Non-contact Operation |

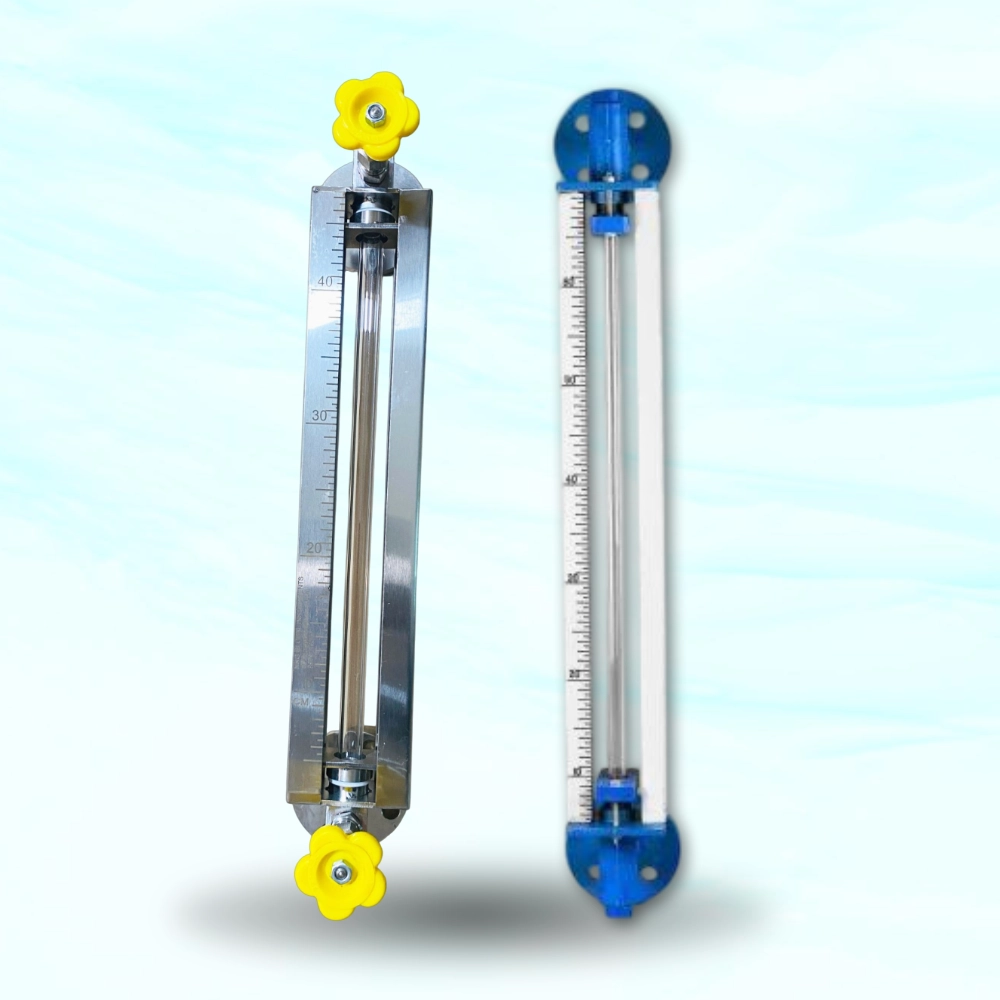

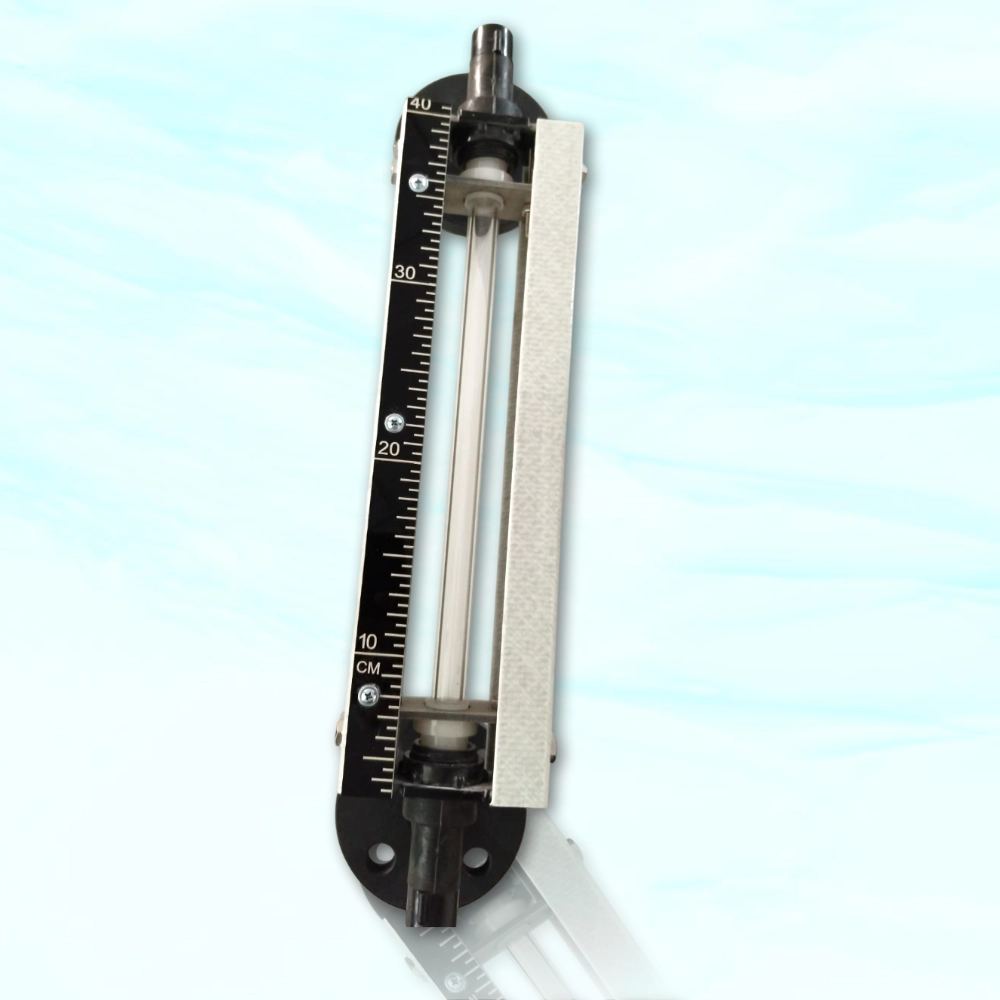

Tubular Level Gauge

A Tubular Level Gauge is a mechanical device designed for visual indication of the liquid level in tanks, vessels, and containers. It consists of a transparent or translucent tube, which is mounted vertically on the side of a tank or vessel, providing a direct view of the liquid level. This device is widely used in industries for simple, reliable, and continuous monitoring of liquid levels in various applications.

Technical Specification

| Specification | Details |

|---|---|

| Material of Construction | Borosilicate Glass, Acrylic, Stainless Steel |

| Temperature Range | -20°C to 200°C (depending on material) |

| Pressure Range | Up to 20 bar (or higher based on design) |

| Mounting | Side-mounted with flange or threaded connection |

| Scale Type | Graduated scale in metric or imperial units |

| Fluid Types | Water, chemicals, oils, and other non-corrosive fluids |

| Indicator | Red/Green liquid level indicator |

| Float Material | Stainless Steel, PVC, PTFE (depending on fluid) |

| Accuracy | ±2% of full-scale output |

| Applications | Water Treatment, Chemical, Food & Beverage, Pharmaceutical |