Key Features

- Withstands high temperatures

- Resists corrosions and chemicals

- Delivers accurate and stable readings

- Fits different industrial applications

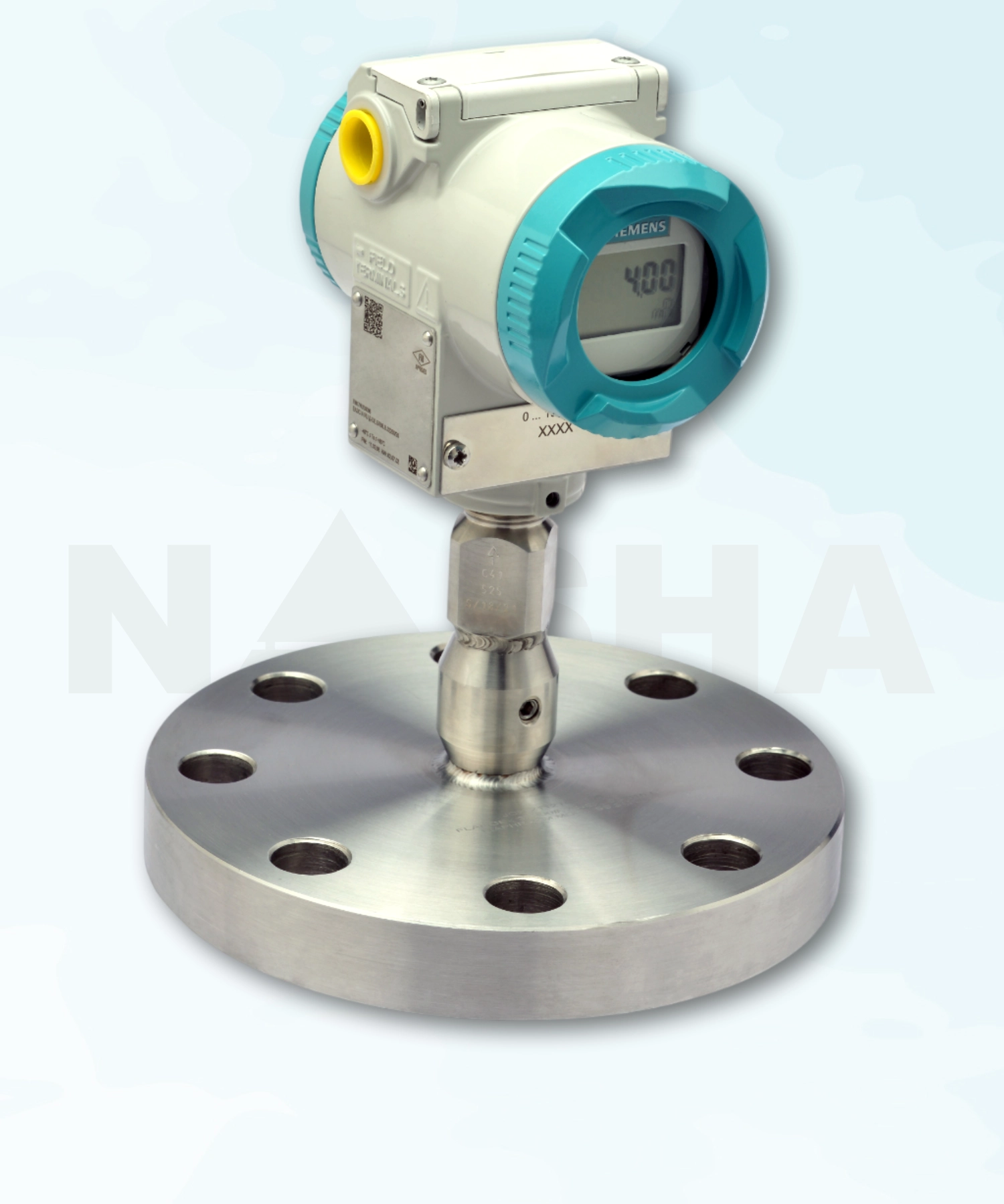

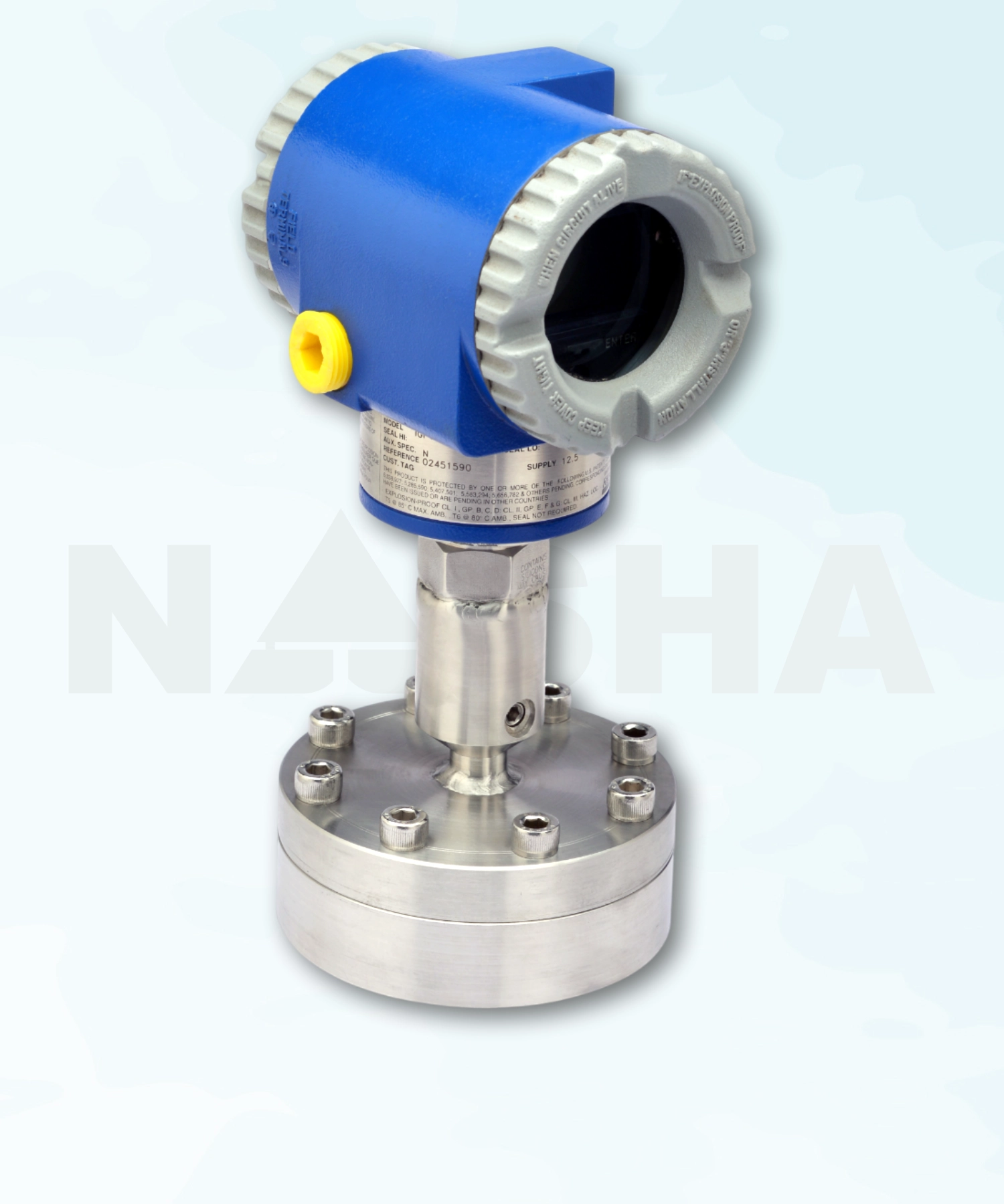

The Leading Remote Seal Diaphragm Manufacturers: Nasha Technomation Diaphragm Seals to Isolate a Pressure Measuring from the Damaging Aspects of Process Media

Turn to Nasha, your trusted remote seal pressure transmitter manufacturers, to protect your sensing elements from harsh conditions. Contrary to the standard pressure transmitters that keep failing, leading to costly shutdowns and other safety risk, our remote seal diaphragm gives precise measurements even in high-temperature environments. Whether it is diaphragm seal pressure transmitters or remote seal diaphragms for PT and DPT, we provide reliable solutions for your industrial requirements. We also provide remote diaphragm repairing, maintenance and calibration services to prevent media contamination, leak prevention, corrosion resistance and ensure temperature stability.

Beyond pressure measurement, Nasha also offers a comprehensive range of level, flow, temperature and pressure instruments such as RTD, thermocouples, controllers and DCS systems. To explore specifics about diaphragm seal differential pressure transmitter, get in touch with the team Nasha.

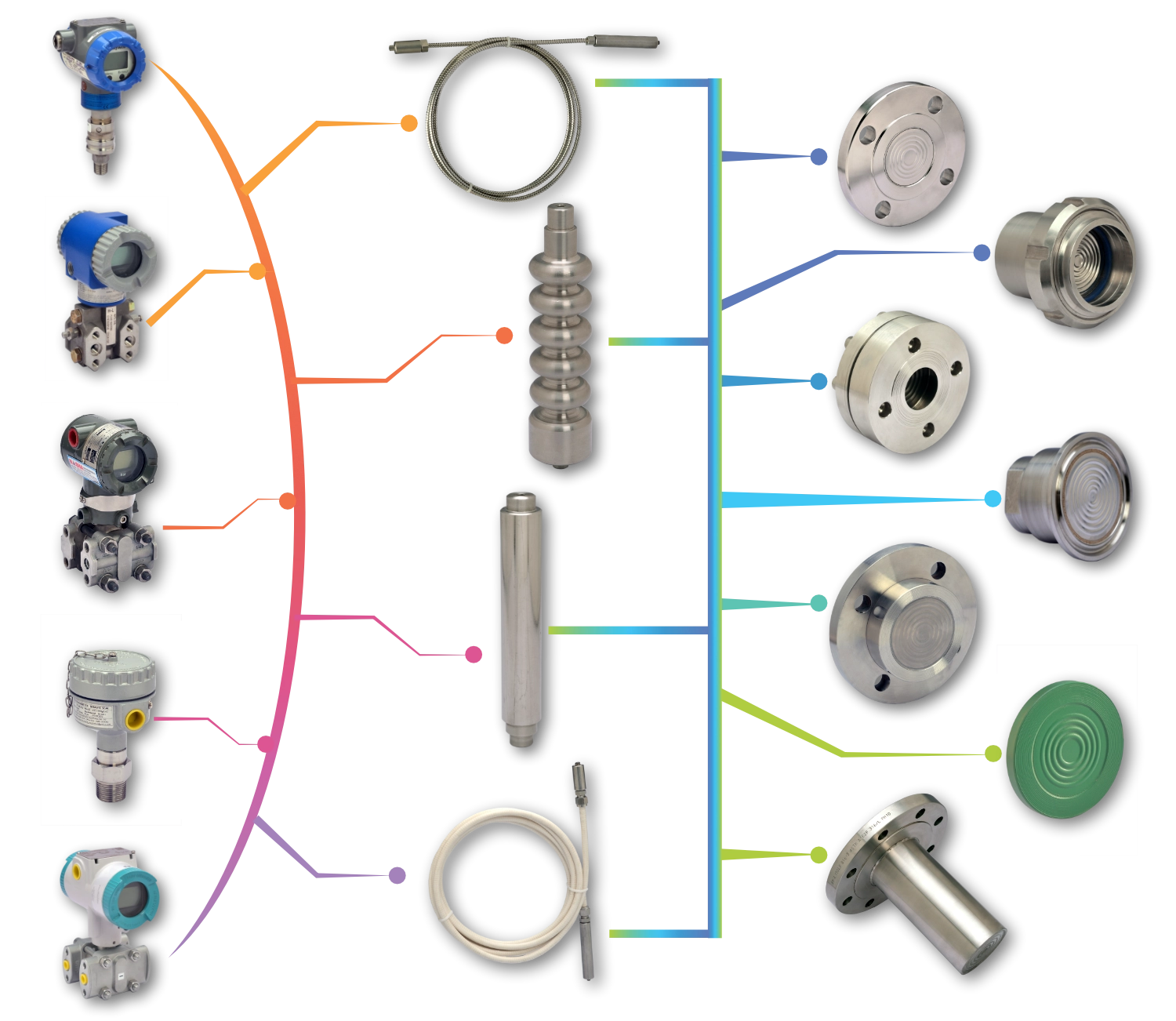

Types Of Remote Seal Diaphragm for PT and DPT

Each pressure transmitter diaphragm is designed to handle specific industrial conditions such as extreme temperatures, high pressure and also corrosive environments.

Nasha Technomation Offers Replacement Components

Nasha Technomation goes beyond just supplying Remote Seal Pressure Transmitters. We also provide replacement components that can keep your processes running smoothly. Instead of replacing the entire system, industries can now opt for specific spare parts and thus reduce downtime and maintenance costs as well.

Nasha offers customized seal solutions:

- Pancake-type remote seals for compact installations

- We provide diaphragm seals in all materials of construction (MOC)

- Large diaphragm seal for high accuracy

- Extended-type seals for highly viscous and dry powder material

- Coated seal diaphragms for highly corrosive fluids

- SMS connections for food-grade and hygienic applications

- PVC capillary options for durable and flexible pressure transmission. Avoid overheating the fill fluid to prevent PVC sheath damage.

Nasha’s commitment to quality and adaptability ensures that businesses are able to maintain peak performance without unnecessary replacements.

Advantages

Explore advantages of our remote seal DPT.

Extends transmitter life

Protecting sensing element and reducing wear and tear.

Minimizing corrosion

The product prevents failures and thus ensures continuous operations.

Accurate result

The product delivers highly precise pressure readings.

Improving safety

seal pressure transmitter reduces risks related to high pressure and hazardous fluids.

Eliminating direct contact

It keeps transmitter safe from viscous media.

Supports distant installations

Diaphragm Seal Differential Pressure Transmitter can work efficiently when it is installed far from the process.

Compatibility with various media

The product is suitable for all liquids, gases, powder, etc.

FAQ's

A remote seal diaphragm is an advanced pressure measurement device. It uses diaphragm seal system to isolate measuring instrument from harsh process media. The pressure is transmitted through a fluid inside capillary tube instead of direct contact. The setup provides:

- Protection from extreme temperatures.

- Accurate readings in challenging conditions.

- Elimination of clogging and crystallization

Industries like petrochemicals, power generation, pharmaceuticals, etc. benefit from this setup.

- Protecting sensitive components from abrasive substances.

- Suitable for aggressive media.

- Minimal risk of contamination.

To know about the features of pressure transmitter diaphragm, particularly for your application or requirements, get in touch with Nasha Technomation team.

Here are the best practices you can follow to maximize the lifespan:

- Check for leaks or fluid degradation periodically. Regular maintenance is important.

- Avoid mechanical cleaning. Use low-pressure flushing methods.

- Check compatibility of process-wetted components with your media.

- Go for annual calibration, especially in case of critical applications.

To know more, get in touch with the leading remote seal pressure transmitter manufacturers Nasha.

What it does:

- Protecting against contamination

- Handling high temperatures without losing accuracy

- Preventing clogging or blockages.

- Working across a wide pressure range.

- Customizable for different fluids.