Pressure

Pressure measurement is a critical parameter in many industrial processes, particularly in industries such as petrochemicals, oil & gas, chemical processing, and power generation. Nasha Automation specializes in providing advanced solutions for pressure measurement, control, and automation, ensuring the safe and efficient operation of systems that require accurate and real-time pressure monitoring.

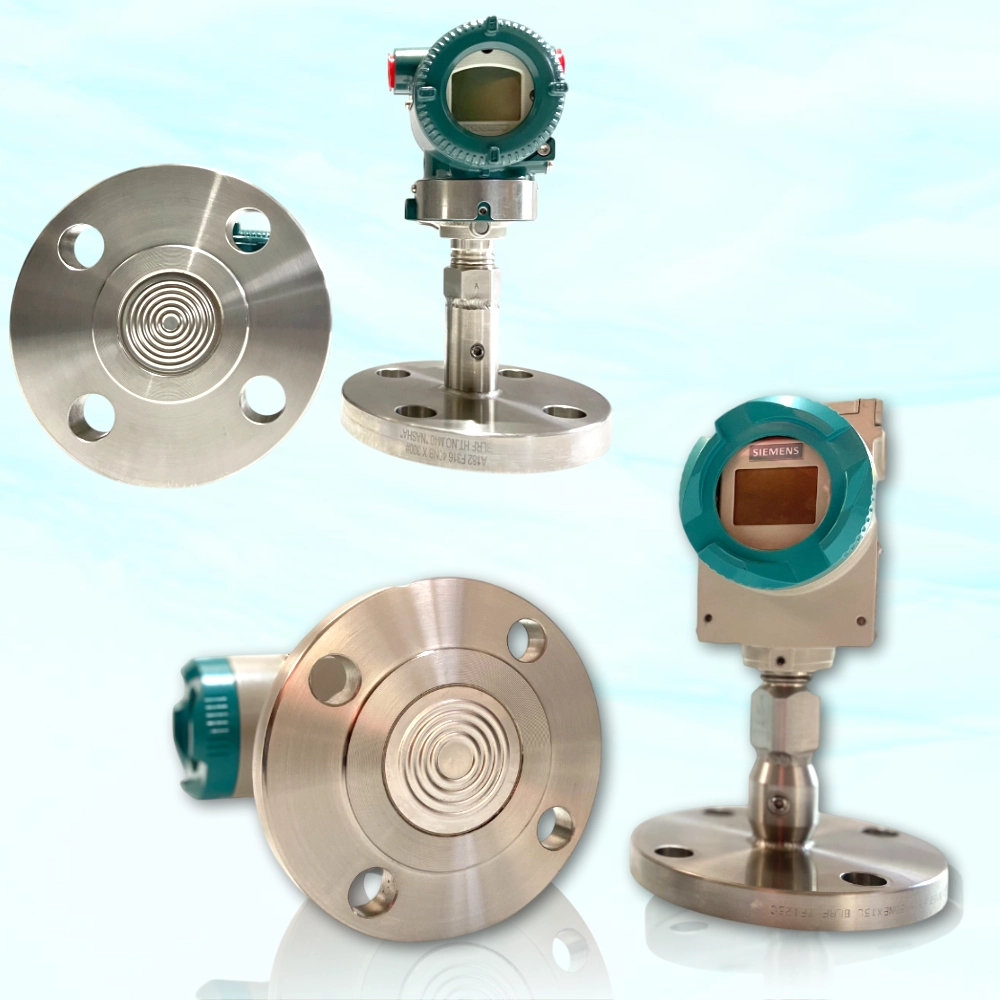

Remote Seal Diaphragm For PT and DPT

A remote seal diaphragm is a specialized component used in conjunction with pressure transmitters (PT) and differential pressure transmitters (DPT) to measure pressure in harsh or difficult-to-reach environments. The diaphragm acts as an interface between the process medium and the pressure transmitter, isolating the sensitive electronics from extreme conditions such as high temperatures, corrosive substances, or high-pressure differentials.

Technical Specification

| Specification | Details |

|---|---|

| Type | Remote Seal Diaphragm for PT and DPT |

| Material | Stainless Steel, Hastelloy, Teflon, Titanium (depending on application) |

| Process Connection | Threaded, Flanged, Welded |

| Seal Fill Fluid | Silicone Oil, Gel, or Other Specialized Fluids |

| Pressure Range | 0-10 mbar to 0-1000 bar (depending on model and application) |

| Temperature Range | -40°C to +250°C (depending on material and fluid type) |

| Accuracy | ±0.5% of Full Scale |

| Compatibility | Compatible with various PT and DPT transmitters |

| Applications | Petrochemical, Chemical Processing, Food & Beverage, Pharmaceutical, Water Treatment |

| Protection | Corrosion-resistant, suitable for harsh or aggressive process conditions |

| Mounting Options | Remote mountable, flexible installation for ease of maintenance |

| Standard Certifications | CE, ATEX (Explosion-proof), UL (optional) |

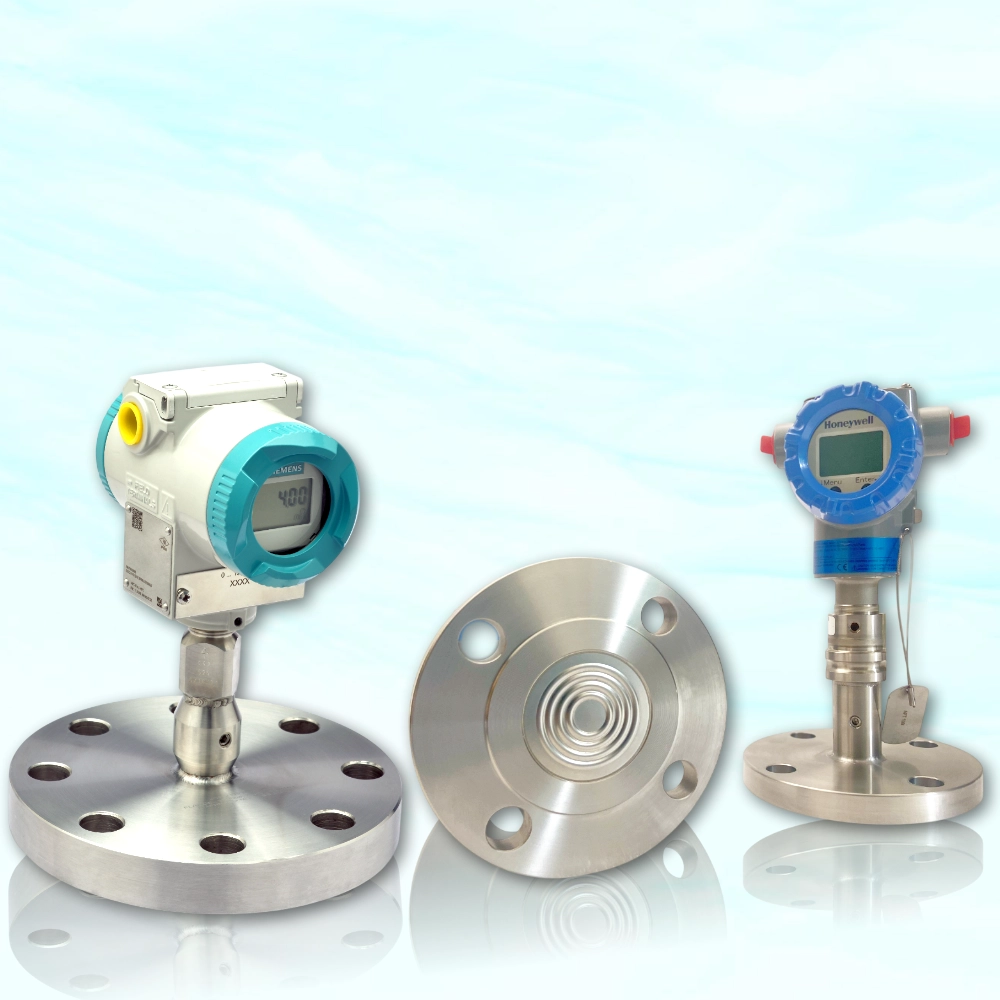

Pressure Transmitter

At Nasha Automation, we offer high-performance Siemens Pressure Transmitters, engineered for precision and reliability in industrial applications. These pressure transmitters are designed to measure gauge, absolute, and differential pressure, ensuring accurate control and monitoring across a wide range of processes.

Technical Specification

| Specification | Details |

|---|---|

| Type | Pressure Transmitter |

| Measurement Range | 0 to 0.1 bar to 0 to 1000 bar (depends on model) |

| Output Signal | 4-20 mA, 0-10 VDC, HART, Modbus, Fieldbus |

| Accuracy | ±0.1% of Full Scale |

| Process Connection | Threaded, Flanged, Welded |

| Materials | Stainless Steel, Titanium, Hastelloy, Teflon (based on application) |

| Temperature Range | -40°C to +125°C (depending on model) |

| Pressure Range | Gauge Pressure, Absolute Pressure, Differential Pressure |

| Power Supply | 24 VDC, 10-30 VDC |

| Explosion-Proof Rating | Exd, Exia, ATEX certified (for hazardous areas) |

| Response Time | Typically < 1 second |

| Communication Protocol | HART, Modbus, Fieldbus (depending on model) |

| Applications | Oil & Gas, Petrochemical, Water Treatment, HVAC, Food & Beverage, Pharmaceutical |

Pressure Transducer

A pressure transducer is a device used to convert the physical pressure of a gas or liquid into an electrical signal. The electrical signal is proportional to the applied pressure, which can then be used for monitoring, controlling, or recording in various industrial applications. Pressure transducers are commonly used in process control systems, automotive, aerospace, and fluid power industries to provide accurate and reliable pressure measurements.

Technical Specification

| Specification | Details |

|---|---|

| Types and Construction | PT100, PT500, PT1000 (100, 500, or 1000 ohms at 0°C); wire-wound, thin-film, or coil construction |

| Type | Pressure Transducer |

| Measurement Range | 0-1 bar to 0-1000 bar (varies by model) |

| Output Signal | 4-20 mA, 0-10 VDC, Modbus, CANBus |

| Accuracy | ±0.25% to ±0.5% of Full Scale |

| Process Connection | Threaded, Flanged, Welded |

| Materials | Stainless Steel, Titanium, Hastelloy, Aluminum |

| Temperature Range | -40°C to +125°C (depending on model) |

| Pressure Range | Gauge, Absolute, Differential Pressure |

| Power Supply | 10-30 VDC (typically 24 VDC) |

| Explosion-Proof Rating | ATEX, Exd, Exia (for hazardous locations) |

| Response Time | Typically < 1 millisecond |

| Applications | Petrochemical, Automotive, Aerospace, Hydraulics, HVAC, Water Treatment |

| Mounting Options | Remote mountable, flexible installation for ease of maintenance |

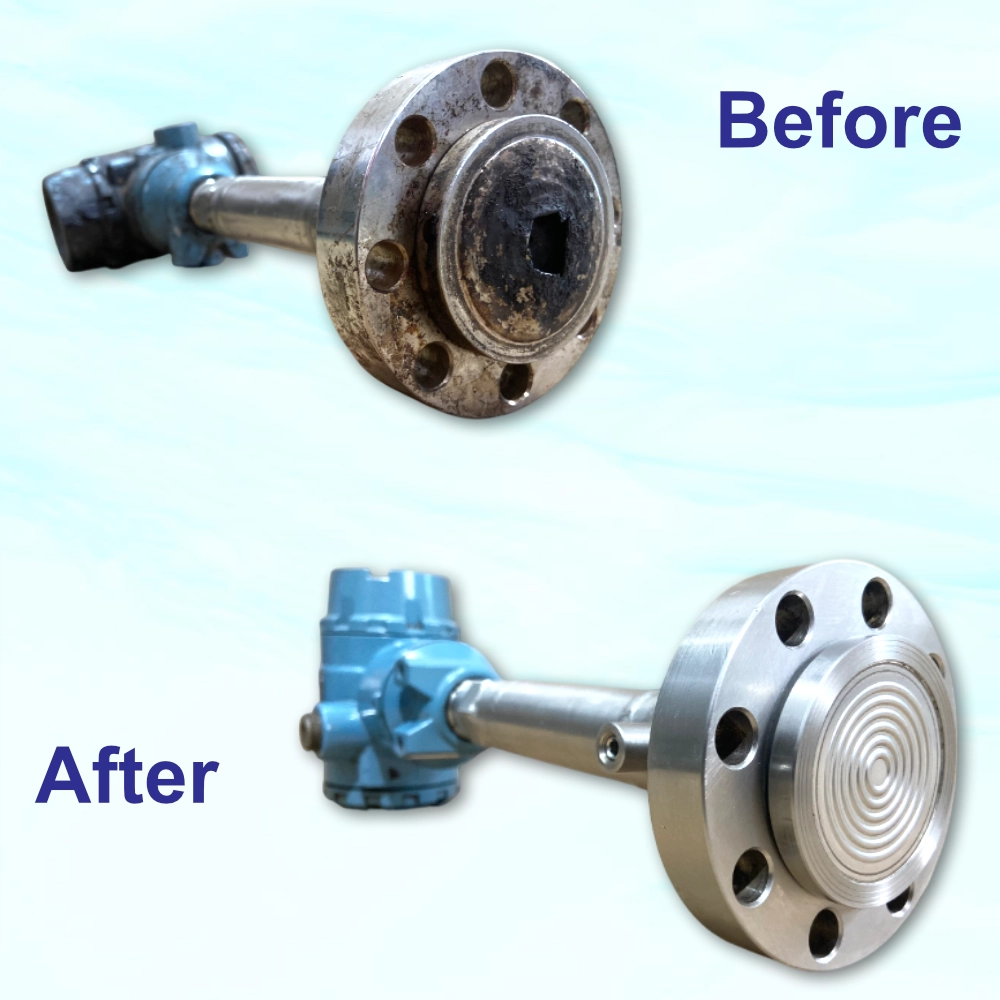

Remote Seal Diaphragm Repair Services For Pt And Dpt

Lorem ipsum dolor, sit amet consectetur adipisicing elit. Recusandae, sit impedit aliquam illum distinctio animi nulla neque veniam, natus porro id pariatur tempore eligendi et ea quaerat deleniti? Eos adipisci iste beatae inventore sit praesentium blanditiis laborum suscipit cum doloribus. Odit porro tempore repellendus nostrum perspiciatis itaque harum at deserunt.