Temperature

Temperature control is essential in the petrochemical and chemical industries, where precise thermal management ensures safe and efficient operations. Nasha Automation specializes in advanced temperature instrumentation and automation solutions that optimize process control, ensuring materials are kept within strict temperature limits to maintain quality, prevent equipment damage, and enhance safety.

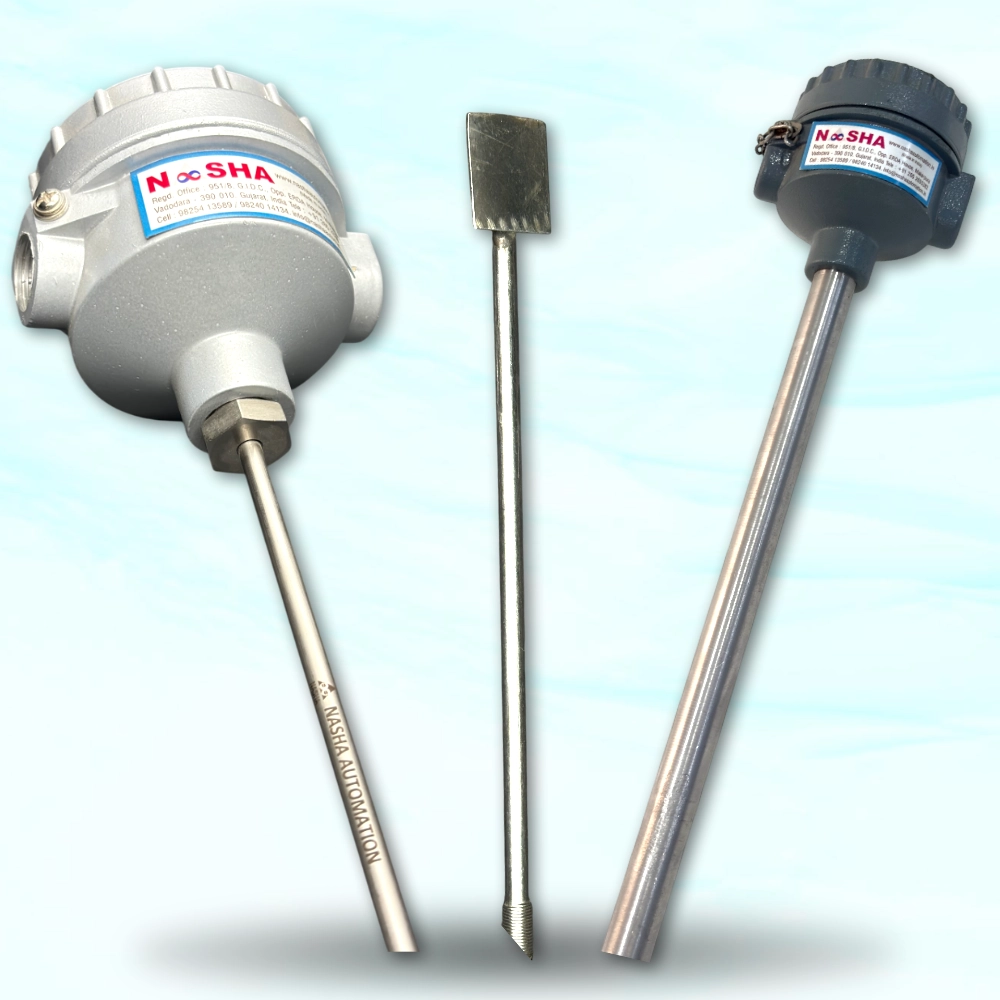

RTD

Resistance Temperature Detectors (RTDs) are high-precision temperature sensors widely used in industrial settings due to their accuracy, stability, and repeatable performance. RTDs operate based on the principle that electrical resistance in materials, typically platinum, changes predictably with temperature. Common types include PT100 and PT1000, where the number represents the resistance in ohms at 0°C.

Technical Specification

| Specification | Details |

|---|---|

| Types and Construction | PT100, PT500, PT1000 (100, 500, or 1000 ohms at 0°C); wire-wound, thin-film, or coil construction |

| Sheath Materials | Stainless steel, Inconel, ceramic |

| Encapsulation | Glass or ceramic for high temperature performance |

| Temperature Range | -200°C to +850°C (depending on type) |

| Accuracy Tolerance | Class A: ±(0.15 + 0.002*t) °C; Class B: ±(0.3 + 0.005*t) °C; 1/3 or 1/10 DIN for high precision |

| Electrical Characteristics | Resistance: 100Ω (PT100) or 1000Ω (PT1000) at 0°C |

| Alpha Coefficient | 0.00385 ohms/°C (standard IEC 60751) |

| Response Time | 1 to 10 seconds, based on design |

| Wiring Configuration | 2-wire (basic), 3-wire (compensated), 4-wire (highest accuracy) |

| Stability | High stability, minimal drift over time |

| Linearity | Near-linear temperature response, more linear than thermocouples |

| Self-Heating Coefficient | 0.05 to 0.3 °C/mW |

| Max Excitation Current | 1 to 5 mA (to avoid self-heating) |

| Max Voltage | Typically under 12V |

| Ingress Protection (IP) | Commonly IP65 or higher for industrial use |

| Shock and Vibration Resistance | High mechanical robustness suitable for industrial settings |

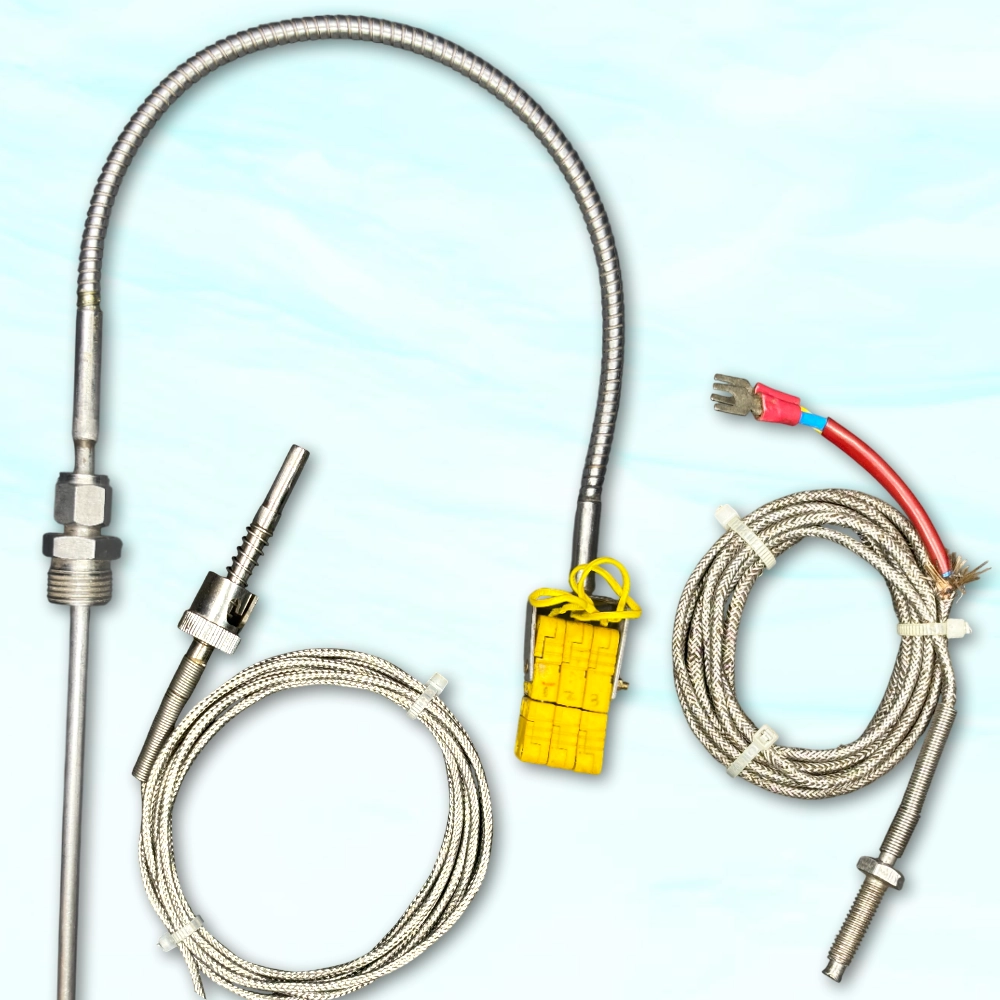

Thermocouple

Thermocouples are widely used temperature sensors that measure heat across a broad range by generating a voltage that correlates with temperature difference. They are composed of two dissimilar metal wires joined at one end, forming a ‘hot junction’ where temperature measurement occurs. This junction produces a thermoelectric effect when exposed to heat, creating a voltage directly proportional to temperature.

Technical Specification

| Specification | Details |

|---|---|

| Types | Common types: J, K, T, E, N, R, S, B |

| Temperature Range | -200°C to +1800°C, depending on type |

| Accuracy | Type-dependent, generally within ±1°C to ±2°C or ±0.75% to ±1.5% of reading for standard thermocouples |

| Sensitivity (Seebeck Coefficient) | Varies by type; for Type K, approximately 41 µV/°C |

| Response Time | Fast response time, typically milliseconds to seconds, depending on size and type |

| Durability | High-temperature resilience; suitable for harsh conditions, corrosion-resistant types available |

| Linearity | Non-linear response; requires compensation or calibration |

| Applications | Industrial furnaces, turbines, boilers, chemical processing, exhaust gas measurement |

| Wiring | Simple two-wire connection |

| Cost | Generally low-cost compared to RTDs, varies by type and environmental resistance |

| Common Sheath Materials | Stainless steel, Inconel, ceramic, depending on environment and temperature |

| Accuracy Class | Class 1 (higher accuracy) and Class 2 (standard accuracy) according to IEC 60584 |

| Cold Junction Compensation | Required for accurate readings, as thermocouples measure temperature difference rather than absolute temperature |

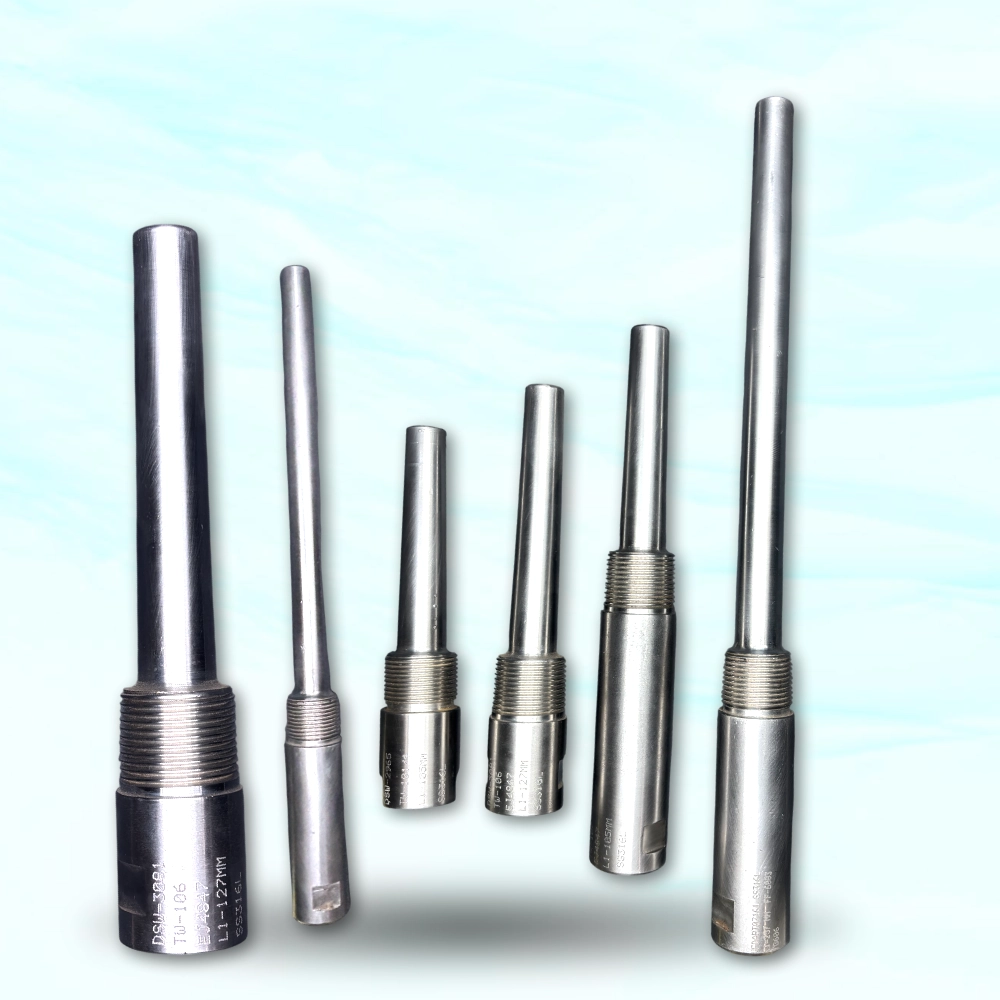

Thermowell

A thermowell is a protective barrier used to house temperature sensors such as thermocouples or RTDs, ensuring they are shielded from the environment in industrial applications. Constructed from durable materials such as stainless steel, Inconel, or other high-temperature alloys, thermowells protect temperature sensors from high-pressure, corrosive, or abrasive environments, while still allowing accurate temperature measurement.

Technical Specification

| Specification | Details |

|---|---|

| Material | Stainless Steel, Inconel, Hastelloy, Ceramic, or other high-temperature alloys |

| Temperature Range | -200°C to +850°C (depending on material) |

| Pressure Rating | Up to 6000 psi (depending on design and material) |

| Length | Customizable to suit pipe size or application requirements |

| Diameter | Varies from ¼" to 2" (depending on sensor and application) |

| Wall Thickness | Varies depending on pressure and temperature conditions |

| End Connection | Threaded, flanged, or weldable for installation |

| Seal Type | Various seals including O-ring, gasket, or compression fitting for leak-proof operation |

| Sensor Compatibility | Compatible with thermocouples, RTDs, and other temperature sensors |

| Corrosion Resistance | High resistance to chemical and corrosive environments, depending on the material |

| Applications | Petrochemical, Chemical Processing, Food & Beverage, Power Generation, Pharmaceuticals |

Temperature Transmitter

A temperature transmitter is an essential device in industrial systems that converts the output of temperature sensors (such as RTDs or thermocouples) into a standardized signal, typically a 4-20 mA or 0-10 V output, suitable for measurement, control, and monitoring systems. Temperature transmitters are designed to provide accurate, reliable, and scalable temperature readings that can be easily interpreted by process control systems or distributed control systems (DCS).

Technical Specification

| Specification | Details |

|---|---|

| Signal Output | 4-20 mA, 0-10 V, HART, Modbus (depending on model) |

| Temperature Range | -200°C to +850°C (depending on sensor type) |

| Accuracy | ±0.1% of full scale or better (depending on model) |

| Power Supply | 12-40 VDC (for 4-20 mA output), 24 VDC (for 0-10 V output) |

| Response Time | Typically less than 1 second (depending on model) |

| Mounting Type | Head-mounted, DIN rail-mounted |

| Input Sensor Type | RTD, Thermocouple, or Thermistor (depending on model) |

| Environmental Protection | IP65, IP67, or IP68 (depending on model) |

| Operating Temperature | -40°C to +85°C (depending on model) |

| Communication Protocol | HART, Modbus, Profibus, Fieldbus (depending on model) |

| Housing Material | Aluminum, Stainless Steel, or Plastic (depending on model) |

| Calibration | Field or Factory Calibration |

| Applications | Oil & Gas, Chemical Processing, HVAC, Power Plants, Food & Beverage |

Temperature Gauge

A temperature gauge is an instrument used to measure and display the temperature of a system or environment. It provides real-time, accurate temperature readings in a wide range of industrial, scientific, and commercial applications. Temperature gauges are typically used in processes where monitoring the temperature is essential for safety, control, and efficiency, such as in manufacturing plants, HVAC systems, laboratories, and food processing.

Technical Specification

| Specification | Details |

|---|---|

| Type | Analog (Dial), Digital, Bimetallic |

| Temperature Range | -50°C to +1000°C (depending on model) |

| Accuracy | ±1% of full scale (depending on model) |

| Output Signal | None (Analog), Digital Display |

| Mounting Type | Panel Mount, Surface Mount, Direct Mount |

| Material | Stainless Steel, Aluminum, Plastic (depending on model) |

| Protection Rating | IP65, IP67 (depending on model) |

| Display Type | Analog Dial, Digital LCD/LED |

| Connection Type | Threaded, Flanged, Welded |

| Temperature Sensor | RTD, Thermocouple, or Bimetallic |

| Operating Temperature | -40°C to +85°C (depending on model) |

| Applications | Industrial, HVAC, Chemical Processing, Food & Beverage, Automotive |